Interview with Lucile Duverger

Meet Futura Gaïa, a company at the cutting edge of technology

Innovating for Sustainable and High-Performance Plant Cultivation

Founded in 2019, Futura Gaïa is a pioneering French company specializing in the cultivation of high value-added plants in a controlled environment on living soil. Through a cutting-edge technological approach combining agronomy, artificial intelligence, and automation, Futura Gaïa supplies the cosmetics, pharmaceutical, nutraceutical, and perfumery industries with premium plant-based ingredients, grown without pesticides and always compliant with the strictest specifications. Based in southern France, the company combines innovation, sustainability, and plant sovereignty.

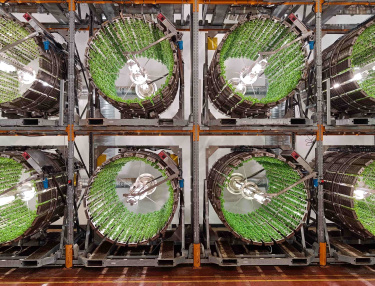

Voltz Vertical Farming

What is your main activity?

We develop crops in a controlled environment on living soil, with the goal of optimizing the concentration of plants’ key active compounds. This approach meets the needs of the health, beauty, and wellness industries, which seek ingredients of impeccable quality, cultivated sustainably and reproducibly all year round and at any production scale, from R&D to large-scale production.

Lucile

Futura Gaïa

Voltz Vertical Farming

How big is your team and where are you based ?

We currently have 22 employees committed to this innovative venture, with nearly a third of the company working in R&D. Our headquarters is in southern France.

We have a research laboratory in Rodilhan (Gard) and a pre-production biofactory in Tarascon (Bouches-du-Rhône). Our two cultivation chambers, located in Tarascon, each have a surface area of 144 m². Thanks to our vertical system, each square meter of floor space is equivalent to about 8 m² of productive open-field area.

Futura Gaia

Tarascon, France

Voltz Vertical Farming

What makes your model unique?

Our differentiation lies in an innovative cultivation system that combines living soil, fully controlled environments, zero pesticides, water efficiency, micro-dosed nutrition, and artificial intelligence. We ensure total traceability, consistent quality, and repeatable production. This model is both environmentally friendly and highly efficient, with annual yields per hectare multiplied by 15 compared to open-field farming.

Our harvests are intended for ingredient manufacturers and industries in cosmetics, health, nutrition, and perfumery. Our clients are looking for plants of optimal quality, pesticide-free, with controlled levels of active compounds and impeccable hygiene. Unfortunately, our highly specific cultivation method does not allow us to obtain the organic label. However, all our crops are guaranteed pesticide-free, and we favor untreated or organic seeds when available.

We have already grown over 1,000 different species, ranging from medicinal plants to aromatics, as well as rare and endangered species. We carry out these projects in co-construction with our partners, in full respect of biodiversity and complete confidentiality.

Medicinal & aromatics

1 000 species

Voltz Vertical Farming

Do you have key figures to illustrate your performance?

Absolutely: our systems consume up to 15 to 20 times less water and 72% less fertilizer than conventional farming. We use 60% less energy than vertical shelf farming systems. Some plants show a +20% increase in calcium or a 13-fold increase in anti-inflammatory activity. In addition, our technologies and expertise allow us, for certain plants, to achieve up to 17 production cycles per year, compared to a maximum of 4 to 5 cycles in traditional farming systems.

Less

water, fertilizer, energy

Voltz Vertical Farming

Do you use artificial intelligence?

Yes, we use AI in several areas. It helps us detect diseases early, monitor crop growth through automated imaging, control energy consumption, and optimize the production of secondary metabolites.

More

productions cycles

Voltz Vertical Farming

What does a typical day look like?

In our laboratory, teams handle sowing, transplanting, harvesting, and crop monitoring. At the biofactory, each day is dedicated to a specific task: sowing, transplanting, harvesting, or even compost grinding for reuse.

Biofactory

Controlling & growing

Voltz Vertical Farming

What about diseases or pests and how do you manage these risks?

Our facilities are protected from most pathogens. However, introducing outside plants can occasionally bring in pests like thrips or aphids. In our model, human hygiene remains the main risk factor.

Prevention is our priority, with strict protocols for operators and quarantine procedures for incoming plants. Our modular system also allows us to quickly isolate a contaminated crop.

Prevention

from contamination

Voltz Vertical Farming

Are there any seasonal constraints?

Total environmental control allows us to overcome seasonal constraints. However, initial supply of plants or bulbs can sometimes be seasonal.

Total

environmental control

Voltz Vertical Farming

What is your approach to soil and water? And for plant fertilization?

We use a French-made soil substrate, which we reuse as much as possible between cycles. The water we use is pre-treated and circulates in a closed system, generating no discharge.

We use only liquid fertilizers applied in very precise quantities according to the daily needs of the plants.

Soil substrate

Local & reused

Voltz Vertical Farming

What is your biggest challenge today?

We still need to convince some industries to prioritize quality, consistency, and sustainability over price, which is often the sole selection criterion. Those who trust us with part of their sourcing are satisfied with the quality of our productions. We hope to gradually expand our share.

We also aim to strengthen our position in the cosmetics and pharmaceutical markets while continuing our research on new high value-added plants.

Production

Quality & research

Which VOLTZ Vertical Farming varieties do you use?

We test and use many varieties from the VOLTZ Vertical Farming catalog. We’ve been collaborating with VOLTZ Maraîchage, particularly the VOLTZ Vertical Farming branch, for nearly 5 years. It is a key partner for sourcing varieties suited to indoor farming.

Depending on current projects and among the references we particularly appreciate, we can mention:

Basil ‘Lucia’, for its adaptability to our system;

Calendula ‘Bonbon’, for its compact growth, short cycle, and abundant flowering;

Pak choi ‘Joi Choi’, for its production potential;

Dill ‘Thalia’ or ‘Hera’;

Coriander ‘Shanghai’, for its short cycle.

We prioritize short-cycle varieties that can withstand the rotation of our systems, with good structure and satisfactory yields.